Introduction

Gas-liquid contactors (GLCs) are one of the core technologies utilized in the chemical industry, which play a critical role for reactant conditioning, chemical conversion and separation processes. Within the scope of this project, we are developing a high-performance falling film reactors for CO2 capture via engineering the way CO2 in gas phase mixes with the liquid absorbent at the reactive gas-liquid interface (micro-mixing phenomena). The major impact of the study will be the performance increase at large scale, which would pave the way for the transition of CO2 capture technologies into practice.

| Principal Investigator: | Karthik Muthukumar |

| Project Manager: | Dr.-Ing. Cihan Ates |

| Researchers: | Andrea Düll, Dr. Thomas Häber |

| Date published: | April 2022 |

| HPC Platform used: | HoreKa |

| Institute: | Institute of Thermal Turbomachinery (ITS), Institute for Chemical Technology and Polymer Chemistry (ITCP) |

| Affiliation: | Karlsruhe Institute of Technology (KIT) |

| Research Field: | Engineering, Chemistry |

| Project ID: | CO2-ABS |

Project Description

Utilization of gas-liquid contact reactors is a popular strategy in the chemical industry for dealing with interfacial transport problems, such as passive cooling systems, gas cleaning units and chemical absorbers. In many reactive systems, as in the case of CO2 absorption, gas molecules are continuously transported from the gas phase to the liquid phase. Depending on the physical and chemical properties of the gas and liquid mediums, the operating conditions and the reactor configuration, the gas molecules exhibit different transportation characteristics. In the case of CO2 absorption, the time scale of reaction is much faster than the time it requires to carry gas molecules to the absorbent liquid and all reactions occur within the liquid film. As a result, reactor performance is dictated by the effective interfacial area between the liquid (solvent) phase and the gas phase.

Methodology

It is possible to enhance the absorption process by a factor of 20 (in average) for the common CO2 absorbents if the interface dynamics is properly tuned [1]. Therefore, there lies a great opportunity to improve the reactor performance via engineering the gas-liquid interface. Realization of this potential, however, requires a thorough understanding of the complex interface dynamics including the transient film thicknesses, velocity distributions and the simultaneous mass transfer process taking place in a very thin liquid layer (<100 μm; for comparison: human hair ~70 μm, white blood cell~25 μm). Experimental studies are extremely difficult at this very thin interface and this is why conducting “virtual experiments” with mathematical models is a key tool for achieving high efficiency.

Simulation of the interfacial mass transfer problem is, nonetheless, still a Herculean task. Prerequisites of a model are (i) accurate and sharp representation of the gas-liquid interface and (ii) ability to capture discontinuities, local penetrations and mixing of the phases. Such capabilities necessitate high computational power: at the fine resolutions needed to capture CO2 absorption, simulation of a 1 m height reactor requires to iterate over 1.3 billion computational elements more than 10 billion times. In other words, the number of the equations to be solved for a single simulation is about 3x1018, equivalent to total number of cells in human bodies for an entire town!(~100,000 people). This colossal computation is managed via our in-house developed code turboSPH[2], which distributes the mathematical operations up to 10,000 cores efficiently.

Current Status and the Outlook

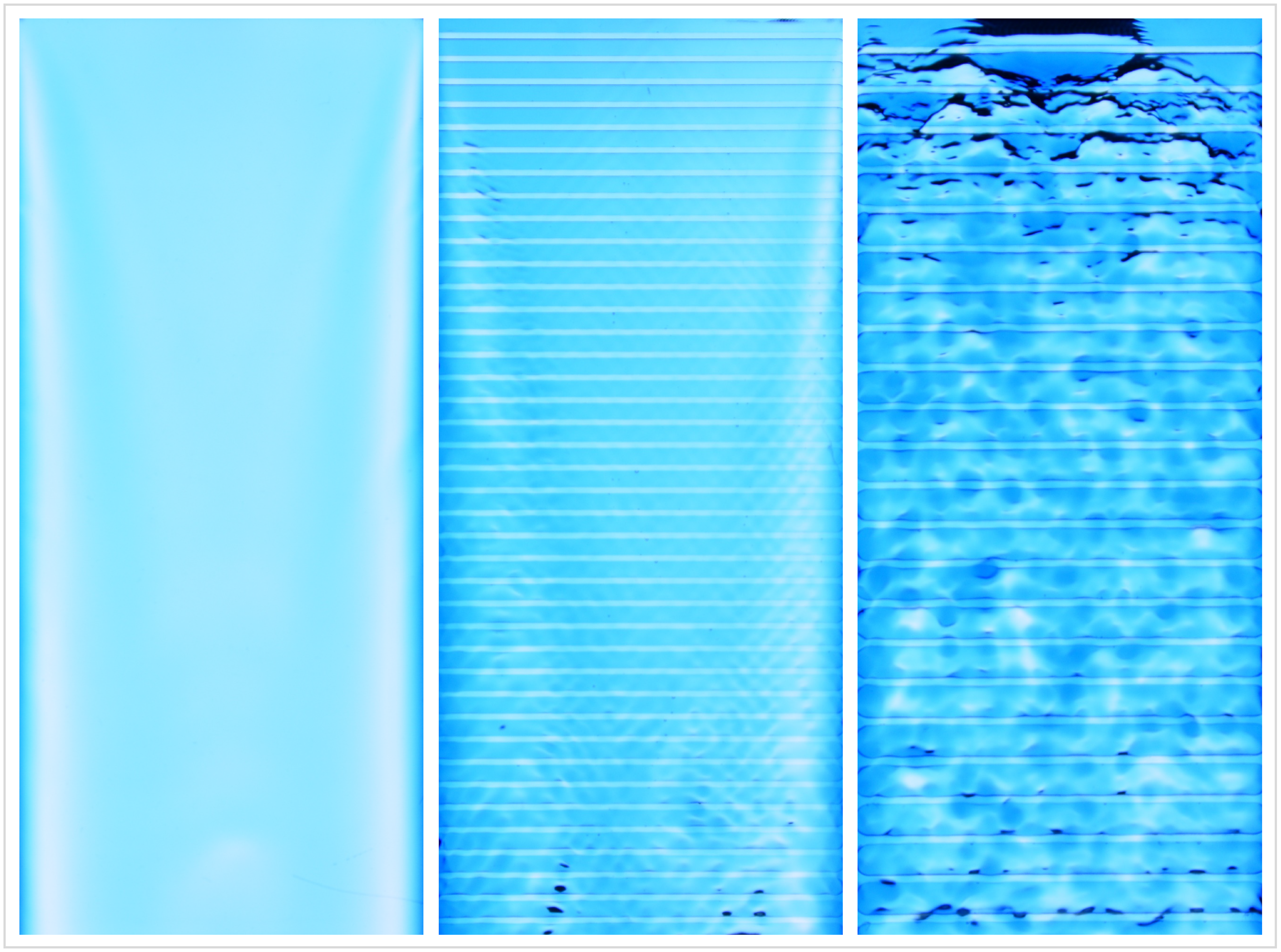

In the first phase of the project, simulations were done to analyse quantities of interest such as velocity components, pressure, density and fluid types. The collected voluminous data is then post-processed to extract how the flow develops within the reactor. This is done by mounting “virtual sensors” along the reactor with 2 cm intervals, which record both the film thicknesses and velocity components. We first validated our methodology for a reference geometry, for which time-averaged experimental results are available. We further identified some practical issues in this basic configuration such as partial wetting of the reactor walls, decreasing the effective interfacial area. Further virtual experiments helped us to optimize the liquid distributor geometry and we were able to solve liquid distribution problem. We also identified other operational effects such as the effect of gas velocity on the gravity driven absorbent flow. Currently we are constructing a demo-reactor to validate our findings before going into the second phase of the project.

We have so far investigated the effects of flow conditioning via distributor plate design and the impact of gas phase velocities on the developing wavy interface. Our methodology has also been confirmed by benchmarking our model predictions with those of theory and available experimental measurements. We are currently testing the effect of different surface functionalization strategies such as coating and surface structuring to further improve the wavy interface. In parallel, we are extending our code to capture the reactive mass transport physics at the interface. All these efforts, we hope, will enable us to create better technologies to combat climate change and its impacts.

References

[1] P. N. Yoshimura et al. Chemical Engineering Science, 51(8):1231–1240, 1996.

[2] Research code turboSPH: SPH meets turbomahinery, url = https://www.its.kit.edu/Versuchsstaende_Forschungscodes_turboSPH.php